In the construction industry, safety is paramount. Workers face numerous hazards, especially when working at heights or in precarious environments.

Among the various safety measures in place, safety net systems play a crucial role in minimizing risk and protecting workers. These systems are designed to prevent fatal falls, reduce injuries, and safeguard both personnel and property.

What Are Safety Net Systems?

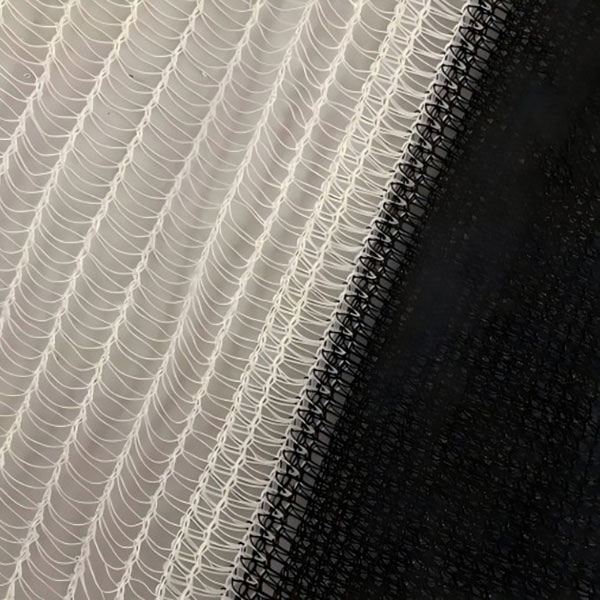

Safety net systems are protective barriers designed to catch and cushion workers or materials that fall during construction activities. Typically made from strong synthetic materials such as nylon or polypropylene, these nets are installed around scaffolding, high-rise buildings, or other construction zones where there is a risk of falling.

Components of a Safety Net System

A safety net system consists of several key components:

-

The Net: The main protective element, made from durable, high-tensile materials.

-

The Support Frame: The framework that holds the net in place, ensuring it remains taut and can withstand impact.

-

Anchoring Mechanisms: These secure the net to the structure or the ground to ensure stability and prevent the net from shifting or collapsing.

Each of these components works together to form an effective safety net system that can handle the force of falling workers or equipment.

How Safety Net Systems Are Installed

Safety net systems are typically installed by trained professionals who ensure the nets are positioned correctly. They must be secured at a height that corresponds with the level of potential fall risk.

Depending on the construction environment, nets may be used around scaffolding, along the edges of building floors, or across wide open spaces where construction activities pose a risk of falling objects.

The installation process involves selecting appropriate materials, determining the correct placement, and securing the system in compliance with safety regulations. In many regions, safety net installation is mandatory as part of the health and safety requirements for construction sites.

Types of Safety Net Systems

There are different types of safety net systems depending on their intended use:

-

Fall Arrest Nets: Designed to catch and stop workers from falling once they lose their footing.

-

Debris Nets: Used to prevent falling debris or tools from hitting workers or pedestrians below.

-

Perimeter Nets: Installed around the edges of high-rise buildings or scaffolding to catch workers or materials.

Each type serves a specific purpose, and construction sites may use a combination of these nets to ensure comprehensive protection.

The Role of Safety Net Systems in Reducing Construction Risks

Construction sites are inherently risky, especially when working at elevated heights or in hazardous conditions. Safety net systems play a critical role in reducing the most dangerous types of accidents — falls.

These systems are designed to catch workers or materials that fall, ensuring minimal injury and damage.

Preventing Fatal Falls

According to statistics, falls from height are one of the leading causes of fatalities in the construction industry. Safety net systems are designed to mitigate this risk by providing a protective barrier.

When a worker falls, the net catches them, absorbing the force of the fall and reducing the likelihood of serious injury or death. This simple yet effective solution can save lives and prevent devastating injuries.

Reducing the Impact of Falling Objects

Construction sites often involve the movement of heavy tools and materials. When these items fall, they can cause significant harm to workers, pedestrians, or bystanders. Safety net systems not only protect workers but also prevent debris from falling onto lower levels, thus safeguarding both the workforce and the general public.

By installing debris nets around work areas, construction sites can reduce the risk of injury from falling objects.

Enhancing Overall Site Safety

In addition to reducing falls and debris hazards, safety net systems contribute to overall site safety by creating a physical barrier that prevents workers from straying into dangerous areas.

This helps to maintain better organization on construction sites and encourages workers to adhere to safety guidelines and protocols.

Safety nets, when properly installed and maintained, help create a more secure work environment for everyone involved.

Benefits of Using Safety Net Systems on Construction Sites

Safety net systems offer several advantages that extend beyond simply protecting workers. These benefits include reduced liability, increased productivity, and compliance with health and safety regulations.

Cost Savings Through Reduced Injury Claims

Accidents on construction sites can result in costly compensation claims, medical expenses, and insurance premiums. By using safety net systems to reduce the likelihood of injuries, construction companies can significantly lower the financial risks associated with accidents.

In the long run, the investment in safety net systems pays for itself through reduced injury claims and insurance costs.

Increased Worker Productivity

When workers feel safe, they are more likely to be focused and productive. Safety net systems provide a sense of security, especially in high-risk areas.

Knowing that there is a protective system in place allows workers to perform their tasks with confidence, without the constant fear of falling. This increased sense of safety often translates into higher productivity and more efficient project completion.

Compliance with Legal and Safety Regulations

Many regions have strict laws regarding construction site safety. In many cases, installing safety net systems is not only recommended but required by law.

By adhering to these regulations, construction companies can avoid fines, legal issues, and work stoppages. Compliance with safety regulations also improves a company’s reputation, making it more attractive to clients and workers alike.

Key Considerations When Choosing a Safety Net System for Construction

Choosing the right safety net system is crucial to ensuring maximum protection. Several factors must be taken into account when selecting the appropriate system for a particular construction site.

Site Conditions and Hazards

Each construction site is unique, and site conditions can vary greatly. Factors such as the height of the building, the type of construction, and the nature of the work being done must all be considered.

A thorough risk assessment should be performed to determine where safety nets are needed most and which type of net is appropriate.

Regulatory Requirements

It’s essential to ensure that the safety net system meets all local and national regulations. Many construction sites are subject to specific safety standards that dictate the installation and use of safety nets.

Understanding these regulations is vital to ensure compliance and avoid legal issues.

Maintenance and Durability

Safety net systems must be maintained regularly to ensure their continued effectiveness. Over time, wear and tear can compromise the net’s ability to protect workers.

It’s important to inspect the nets regularly for signs of damage and replace them as necessary to ensure they remain in optimal condition.

Best Practices for Implementing Safety Net Systems on Construction Sites

To maximize the effectiveness of safety net systems, construction companies must implement best practices during installation and use. These practices ensure that safety nets are properly utilized and maintained.

Proper Installation and Securing of Nets

Safety nets should be installed by trained professionals who are familiar with the standards and guidelines for their use.

Proper installation involves securing the net at the correct height, ensuring that it is taut, and attaching it to stable structures to prevent it from shifting during use. Adequate training and supervision are also crucial to ensure nets are used effectively.

Regular Inspections and Maintenance

Once installed, safety net systems must be inspected regularly to check for damage or wear. Nets should be checked for any tears, fraying, or weakened areas, and repaired or replaced as necessary.

Additionally, workers should be trained to recognize when a net is compromised and take appropriate action.

Educating Workers on Safety Net Use

Workers should be educated on the importance of safety net systems and how to work safely around them.

Proper training helps ensure that safety nets are used correctly and that workers follow all safety protocols to prevent accidents. Workers should also be made aware of the risks associated with not using the nets properly.

Conclusion

Safety net systems are designed to reduce risks and enhance safety in construction, protecting workers from falls, preventing injuries from falling objects, and contributing to a safer overall work environment.

By implementing these systems, construction companies can minimize hazards, comply with regulations, and improve productivity. Investing in safety net systems is not only a legal and ethical responsibility but also a smart business decision that offers long-term benefits.

Prioritizing safety helps protect both workers and the company’s bottom line, making construction sites safer for everyone involved.