Factors to Consider When Buying Insulated Tarps For Concrete

- Insulation Material & R-Value – Look for tarps with good thermal insulation (high R-value) to retain heat in cold conditions or block excessive heat in hot conditions. The better the insulation, the more consistent the concrete curing.

- Size & Coverage – The tarp should fully cover the pour area, including edges. Oversized tarps are better than undersized ones to avoid heat loss or exposure to weather.

- Durability & Material Strength – Concrete work can be rough. Choose tarps made from strong, tear-resistant materials like reinforced polyethylene or heavy-duty fabric that can handle repeated use and tension.

- Water Resistance – Concrete needs moisture for proper curing. A tarp should prevent rain or snow from pooling on the surface while not letting water soak through.

- Ease of Handling – Lightweight tarps with handles or grommets make installation and removal faster, especially on large pours.

- Temperature Range – Check the manufacturer’s recommended operating temperatures. Some tarps perform better in extreme cold, while others are designed for moderate conditions.

- UV & Weather Protection – For outdoor projects, UV resistance prolongs tarp life. Weatherproofing helps the tarp withstand wind, snow, or rain without tearing or losing insulation efficiency.

- Reusability & Cost – High-quality tarps may cost more but can be reused across multiple projects, making them more economical over time.

FAQ

1. What is the R-value of your insulated tarps?

While a specific R-value is not explicitly rated for our tarps, they are designed with a high R-value and feature a closed-cell PE foam core for superior thermal performance. The insulation is engineered to lock in hydration heat for optimal concrete curing and reduce energy consumption in temporary enclosures, making them a highly effective solution.

2. Are these tarps waterproof and UV-resistant?

Yes, our insulated tarps are both waterproof and UV-resistant. The outer skin is made from a heavy-duty, UV-stabilized polyethylene that provides long-lasting protection against rain, moisture, and sun exposure. This design helps protect your materials and equipment from elemental damage and contributes to the overall durability of the tarp.

3. What is the difference between polyethylene and vinyl tarps?

Both polyethylene and vinyl are widely used materials for insulated tarps. Polyethylene (HDPE) is a strong, woven material that provides effective waterproof and UV resistance for a variety of construction applications. Vinyl, on the other hand, is often described as a heavier and more durable material that is more resistant to tears and abrasions, offering a longer lifespan. The choice between them often depends on the specific project’s durability and longevity requirements.

4. Can these tarps be customized to a specific size?

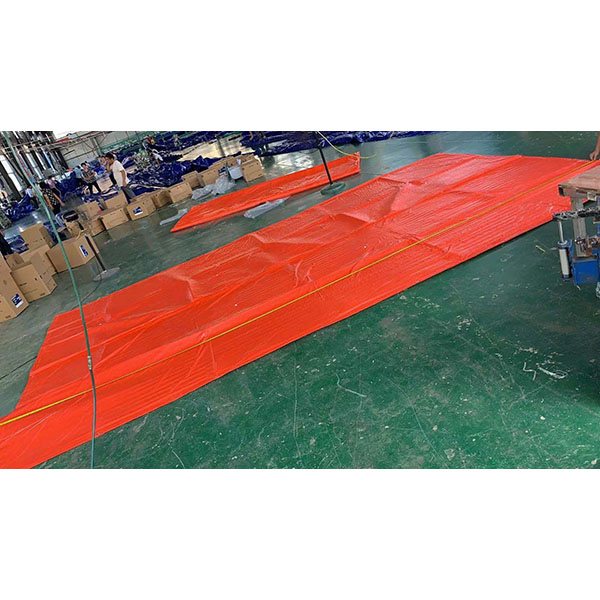

Yes, custom sizing is available upon request [Image 1]. We specialize in providing custom-made tarps to meet the unique requirements of industrial and commercial projects, ensuring you get the exact size you need for your application.

5. How long do insulated tarps last?

Our insulated tarps are designed for long-term durability and are a reusable solution for professional projects. Constructed with high-quality, durable materials, they are built to withstand harsh weather conditions, abrasions, and tears, making them a reliable and cost-effective asset for repeated use across various job sites.