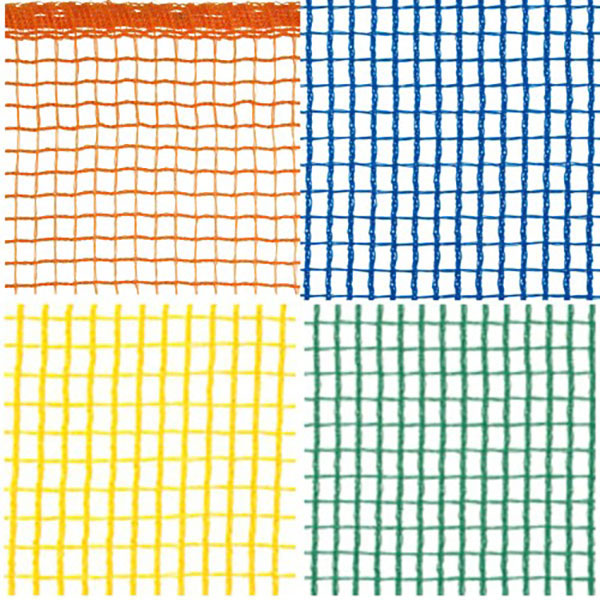

Material & Construction: High-Density Knitted Polyethylene (HDPE) Mesh

- Core Material: The netting is constructed from UV-stabilized, high-density polyethylene (HDPE). This material is chosen for its exceptional durability and moisture, and its overall cost-effectiveness.

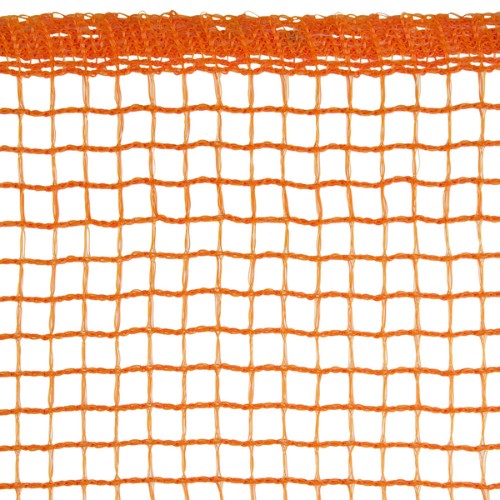

- Knitted Construction: The “warp-knitted” design (as specified in the datasheet) is superior to a woven mesh for this application. It makes the netting highly flexible, resistant to fraying, and prevents it from unraveling when cut, which is crucial for custom fitting on site.

- UV Stabilization: The inclusion of UV inhibitors protects the polymer chains from solar degradation, ensuring the netting maintains its strength and integrity over long periods of outdoor exposure.

- High-Density: This denotes a tight, robust mesh structure that enhances its ability to withstand impact and resist tearing, contributing to its long service life.

Mesh Specifications: 3.5 oz (~100 GSM) with 1/4″ Openings

- Weight (GSM): The weight of 3.5 oz per square yard (approximately 100 grams per square meter) represents a standard weight option. The product is also available in heavier weights (130 GSM, 150 GSM), which offer increased durability and debris-stopping power for more demanding applications.

- Mesh Size: The 1/4-inch hole openings are small enough to effectively contain a wide range of debris, from large tools and fragments to fine dust and concrete chips. This size also provides the optimal balance between debris containment and wind flow, reducing sail effect.

Reinforced Edges: Hemmed + Webbing

- Hemmed Finish: The edges are folded over and stitched to create a clean, durable, and fray-resistant border.

- Webbing Reinforcement: A heavy-duty webbing (typically from nylon or polyester) is sewn over the hem. This webbing is the critical load-bearing component; it distributes the installation tension evenly across the entire length of the netting, preventing the lightweight mesh itself from bearing the direct stress. This creates strong, reliable anchor points for grommets or ties, ensuring secure fastening to scaffolding or structures without risk of tearing.

Critical Safety Feature: Flame Retardancy (NFPA 701)

The netting is treated to be flame retardant and meets NFPA 701 Test Method II standards. This means the material has been rigorously tested and will resist ignition and prevent the rapid spread of flame. This is a non-negotiable safety feature on construction sites, especially where welding, grinding, or other hot work is performed, as it significantly reduces fire hazard.

Performance and Environmental Resilience

- Cold Weather Flexibility: The polyethylene material remains pliable and does not become brittle in cold temperatures, allowing for easy installation and reliable performance year-round, even in freezing conditions.

- Will Not Unravel When Cut: A direct benefit of the knitted construction, this allows crews to quickly customize the size of the netting on-site without needing to heat-seal the edges, saving time and effort.