Custom Insulated Tarps China Manufacturer and Supplier

Agrishade is a professional manufacturer and supplier of waterproof insulated tarps. We provide high-quality tarps that deliver reliable temperature control and insulation for diverse industies. Our insulated tarps are widely applied in construction, transportation, agriculture, and cold chain logistics. They are available for bulk orders and offer custom options, focusing on durability and effective insulation for large-scale projects.

Key Features of Insulated Tarps

- Engineered Insulation: Multi-layer design retains heat or cold effectively.

- Durable Construction: Outer shell resists tearing, abrasion, and UV damage.

- Moisture Barrier: Prevents condensation and water infiltration.

- Custom Dimensions: Produced to client specifications for large-scale use.

- Secure Fastening: Reinforced hems and grommets support heavy-duty installation.

- OEM Flexibility: Adaptable to branding, private labels, and thermal needs.

Agrishade Thermal Insulated Tarp Series

Temperature exposure is a persistent challenge in industrial and manufacturing operations. Equipment and materials are often subjected to heat loss, moisture, and rapid temperature fluctuations, especially during outdoor work, maintenance shutdowns, or temporary installations where permanent insulation is impractical.

Insulated tarps address these conditions by combining mechanical protection with thermal insulation. They reduce heat transfer, limit environmental exposure, and help stabilize operating temperatures without requiring structural modifications. Designed for outdoor equipment, construction materials, and industrial machinery, insulated tarps protect against rain, wind, and UV exposure while minimizing heat loss and condensation.

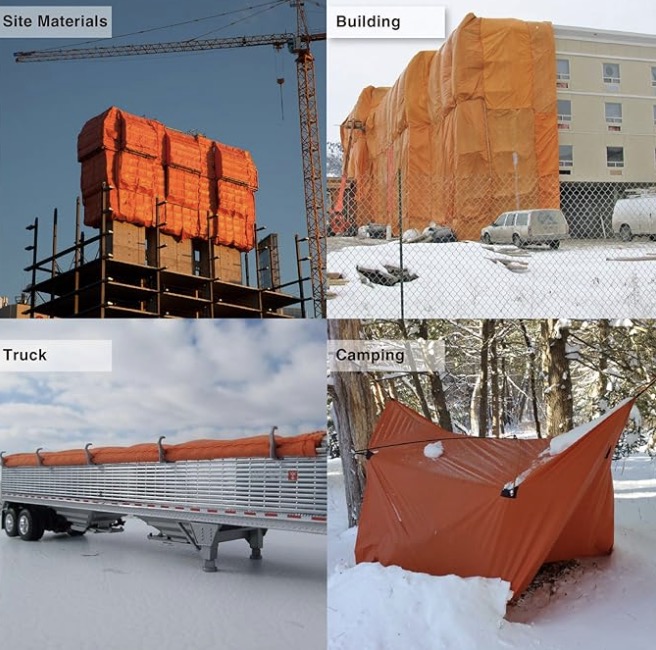

Reinforced construction allows secure installation in demanding environments and supports reliable use across warehouses, construction sites, vehicles, and temporary shelters. Available in custom sizes and colors to match your needs.

Why Choose Agrishade as Your Supplier

Agrishade combines manufacturing expertise with global export capabilities. We manage the full production cycle, ensuring consistent quality across large orders. Our strength lies in OEM customization, enabling businesses to order tarps that reflect their own brand or project requirements.

By choosing us, clients secure a dependable supplier that delivers bulk volumes on time, with flexibility for special requests. Our long-term partnerships are built on reliable supply, technical precision, and solutions designed for professional industries.

More Information

Customizable Options for Insulated Tarps

| Customization Item | Description |

|---|---|

| Base Fabric Material | The outer layer is typically made from durable fabric combined with PE. |

| Insulation Layer Material | Foam, bubble insulation, or multi-layer composite insulation materials can be used to reduce heat loss or block low temperatures. |

| Insulation Thickness | Thickness can be customized according to insulation requirements. Increased thickness improves thermal performance but also affects overall weight and flexibility. |

| Size and Shape | Length, width, and special shapes can be customized to fit equipment, containers, or specific coverage areas. |

| Edge Reinforcement Method | Edges can be reinforced by heat sealing, stitching, or webbing to improve durability and reduce the risk of tearing. |

| Grommet Specifications and Spacing | Grommet material, diameter, and spacing can be customized to suit different load conditions and fixing methods. |

| Fixing Methods | Multiple fixing options are available, including straps, buckles, hook-and-loop fasteners, or D-rings, to improve installation efficiency and stability. |

| Color Options | Colors can be customized to enhance on-site visibility or align with brand identity. |

| Waterproof Performance | Waterproof levels can be specified based on the operating environment, suitable for outdoor use, transportation, and harsh weather conditions. |

| Flame Retardant Performance | Flame-retardant materials or treatments can be added to meet construction site or industry safety standards. |

Benefits of Agrishade Insulated Tarps

Agrishade‘s insulated tarps trap heat to protect temperature-sensitive materials like concrete, machinery, and equipment from cold weather. They block wind, rain, and snow, keeping items dry and secure. Designed to withstand harsh outdoor conditions, these heavy-duty tarps are durable and long-lasting.

Reinforced edges and secure fastening points ensure reliable placement, providing consistent thermal insulation and weather protection. Our insulated tarps help prevent material damage, reduce heat loss, and extend the lifespan of equipment and structures in demanding environments.

Applications of Heavy Duty Insulated Tarps

- Concrete Curing Protection: Maintains stable temperatures to prevent cracking and ensure proper setting.

- Equipment and Machinery Coverage: Shields machinery from cold, wind, rain, and snow, reducing downtime and damage.

- Construction Site Weather Protection: Covers building materials and temporary structures, enabling work in harsh conditions.

- Industrial and Outdoor Storage: Protects stored materials and outdoor inventory from moisture, extreme temperatures, and environmental exposure.

- Energy and Utilities: Insulated tarps are used around valves, flanges, and temporary piping in power generation and utility operations. They support energy efficiency and worker safety.

Understanding Insulated Tarps in Detail

What Are Insulated Tarps

Insulated tarps are multi-layer protective covers that combine mechanical protection with thermal insulation. Unlike standard tarps, which focus mainly on weather resistance, insulated tarps are engineered to slow heat loss or heat gain.

You typically use insulated tarps in situations where temporary thermal control is required. This includes protecting equipment during cold weather, maintaining curing temperatures, covering heated components, or reducing energy loss in exposed processes.

From a functional standpoint, insulated tarps act as flexible thermal barriers. They do not generate heat or cooling. Instead, they help you preserve existing temperatures and reduce exposure to ambient conditions.

How Insulated Tarps Work

Insulated tarps work by limiting heat transfer through conduction, convection, and radiation. Their layered construction plays a key role in this process.

The outer layer blocks wind, moisture, and direct environmental contact. This reduces convective heat loss. The internal insulation layer slows conductive heat flow between surfaces and the surrounding air. In some designs, reflective layers are added to reduce radiant heat transfer.

When properly installed, insulated tarps create a controlled micro-environment. This allows you to stabilize temperatures for longer periods without relying solely on active heating systems.

Material Structure and Construction

The performance of insulated tarps depends heavily on their materials and construction quality. Understanding these elements helps you select the right product for your application.

Outer Protective Layer

The outer layer is typically made from reinforced PVC, vinyl-coated polyester, or heavy-duty synthetic fabric. Its primary role is durability.

This layer resists tearing, abrasion, UV exposure, and moisture ingress. In industrial environments, insulated tarps are frequently dragged, folded, and fastened repeatedly. A strong outer layer ensures consistent performance over time.

Insulation Layer

The insulation layer is the core component of insulated tarps. Common materials include closed-cell foam, fiberglass batting, or composite thermal materials.

Closed-cell foam is often preferred in industrial use because it resists moisture absorption and maintains insulation performance in wet conditions. Fiberglass offers good thermal resistance but requires proper encapsulation to avoid moisture issues.

The thickness of this layer directly affects thermal performance. Thicker insulation generally provides better heat retention but also increases weight and handling complexity.

Inner Liner

Some insulated tarps include an inner liner that protects the insulation layer and provides a clean contact surface. This liner may be smooth, reinforced, or reflective depending on the application.

In high-temperature environments, reflective liners help reduce radiant heat exposure. In cold environments, smooth liners prevent moisture accumulation and simplify cleaning.

Key Performance Characteristics

When evaluating insulated tarps, you should focus on measurable performance factors rather than general descriptions.

Thermal Resistance

Thermal resistance indicates how effectively the tarp slows heat transfer. While insulated tarps are not rated like permanent building insulation, material thickness and insulation type give you a practical performance benchmark.

For cold-weather applications, higher insulation density and thicker cores provide better results.

Waterproof and Weather Resistance

Most insulated tarps are designed to be waterproof or water-resistant. This is critical because moisture reduces insulation effectiveness.

Seam construction, coating quality, and edge reinforcement all influence weather resistance. Poor seam sealing can allow water ingress and compromise thermal performance.

Mechanical Strength

Industrial insulated tarps must withstand mechanical stress. This includes pulling, fastening, wind load, and repeated handling.

Look for reinforced edges, grommets, or fastening loops designed for industrial use. Weak attachment points are a common failure area.

Advantages of Using Insulated Tarps

Insulated tarps offer several practical advantages in industrial settings.

They provide flexible thermal protection without permanent installation. You can deploy them quickly and remove them when conditions change.

They help reduce energy consumption by minimizing heat loss. This is especially valuable during temporary heating operations.

They protect equipment and materials from temperature-related damage. This includes freezing, condensation, or overheating.

They are reusable and adaptable. One set of insulated tarps can serve multiple applications across different sites.

Limitations and Considerations

Despite their benefits, insulated tarps are not a universal solution.

They do not replace permanent insulation systems for long-term applications. Their performance depends on proper installation and coverage.

Improper fastening can allow air gaps that reduce thermal effectiveness. You must ensure full coverage and secure attachment.

Weight and handling can be a concern for large or thick insulated tarps. This may require additional labor or equipment during installation.

Understanding these limitations helps you apply insulated tarps where they deliver the most value.

Best Practices for Installation and Use

To maximize performance, you should follow best practices when using insulated tarps.

Ensure full surface coverage. Gaps reduce thermal effectiveness.

Secure all edges properly. Wind movement increases heat loss.

Avoid compressing the insulation layer excessively. Compression reduces insulation performance.

Inspect tarps regularly for damage, especially at seams and attachment points.

Proper installation significantly improves real-world performance.

Maintenance and Service Life

Maintaining insulated tarps is relatively straightforward.

Clean the surface regularly to remove debris and contaminants. Use mild cleaning agents to avoid damaging coatings.

Dry tarps fully before storage. Moisture trapped inside can degrade insulation materials.

Store tarps flat or loosely rolled. Tight folding can damage insulation layers over time.

With proper care, industrial insulated tarps can deliver consistent performance over multiple years.

FAQ

1. What is the difference between a tarp and a tarpaulin?

A tarp and a tarpaulin are basically the same. The word “tarpaulin” is the full term, while “tarp” is just a shorter version. Both are large sheets made from durable materials like polyethylene, canvas, or vinyl, used to cover or protect objects from weather, dust, or dirt. In short, a tarp is just a convenient name for a tarpaulin.

2. How effective are insulated tarps?

Insulated tarps are effective at controlling temperature and protecting against weather. They can block cold wind, trap heat, and reduce moisture. The level of effectiveness depends on the material and the number of insulation layers. High-quality insulated tarps provide good protection for outdoor work, camping, or storage, helping prevent damage from cold, rain, or frost.

3. Do insulated tarps work in winter?

Yes, insulated tarps work in winter. They help keep warmth inside tents, shelters, or storage areas by reducing heat loss. The insulation layer blocks cold air and prevents frost or ice from forming on covered surfaces. While they do not replace heaters, they make cold conditions more manageable and protect equipment, vehicles, or outdoor workspaces from harsh winter weather.

4. What is a good thickness for a heavy-duty tarp?

A ideal thickness for a heavy-duty tarp is usually between 10–16 mils (0.25–0.4 mm) for polyethylene tarps. Vinyl tarps may be thicker, around 18–20 mils. Thicker tarps are stronger, more durable, and better at resisting tears, wind, and rain. Choosing the right thickness depends on the intended use, such as covering vehicles, construction sites, or outdoor equipment.

5. Are insulated tarps waterproof?

Yes, insulated tarps can be waterproof. Many insulated tarps are made with materials like polyethylene or vinyl that resist water. The insulation layers can also include a waterproof barrier to keep rain or snow out. A waterproof insulated tarp is ideal for protecting equipment, storage areas, or temporary shelters from wet weather while maintaining temperature control.