Knitted Shade Net uses a flexible structure that stretches easily and resists tearing. Woven shade nets offer less stretch, but they provide higher shade density and withstand tough weather. Both types protect crops and outdoor spaces from ultraviolet rays, but their construction affects installation and long-term performance.

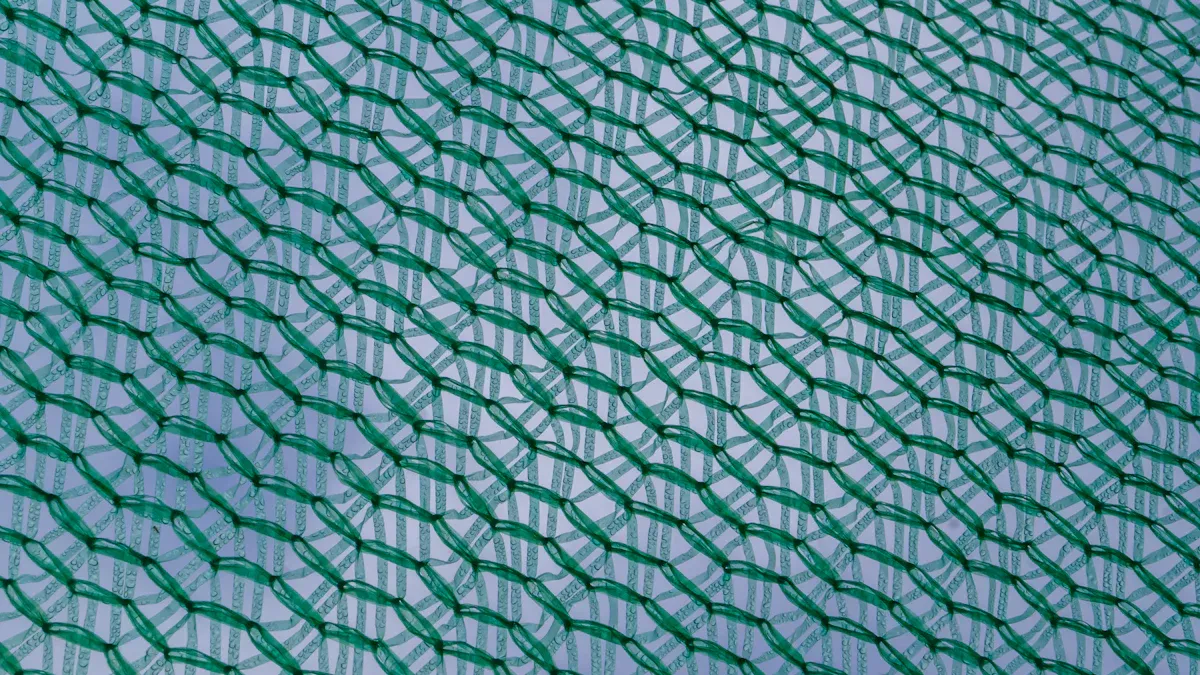

Knitted Shade Net

Construction

Knitted shade net uses a series of interlocking loops made from high-density polyethylene. This method creates a fabric that does not unravel when cut. The open weave of knitted shade net allows air and light to pass through easily.

Durability

Knitted shade net resists tearing and fraying, even after long exposure to sunlight. The material stands up well to wind and weather. Many growers choose knitted shade net because it lasts for several seasons.

Flexibility

Knitted shade net stretches without losing its shape. This flexibility makes it easy to cover uneven surfaces or wrap around structures. The netting returns to its original form after being pulled or bent.

Installation

Knitted shade net installs quickly and does not require special tools. Users can cut the net to size without worrying about frayed edges. The lightweight design of knitted shade net makes it simple to handle and move.

Uses

Gardeners and farmers use knitted shade net to protect plants from harsh sunlight. Homeowners often choose knitted shade net for patios, greenhouses, and animal enclosures. The net also provides ventilation, which helps prevent heat buildup under the covered area.

Knitted shade net offers a balance of shade and airflow. People use knitted shade net in nurseries, sports facilities, and outdoor events. The net adapts to many environments and needs.

Knitted shade net remains popular for its stretchability, longevity, and ease of installation. Many users prefer knitted shade net for its simple maintenance and reliable performance. The net supports healthy plant growth by reducing stress from intense sunlight.

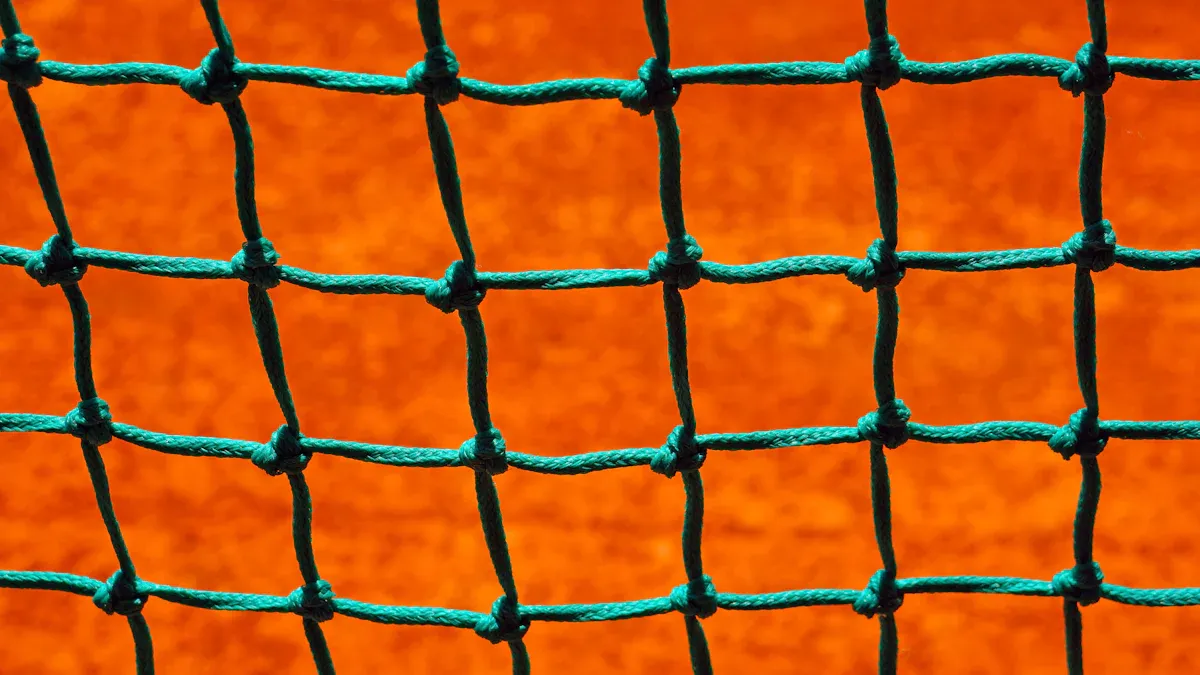

Woven Shade Net

Construction

Woven shade net uses flat tapes of high-density polyethylene. Manufacturers weave these tapes together in a crisscross pattern. This process creates a strong and stable fabric.

Woven shade net does not stretch much. The tight weave gives the material a firm and rigid feel. The edges often require extra reinforcement, called edge tapping, to prevent fraying.

Durability

Woven shade net stands up well to harsh weather. The dense weave resists damage from wind, rain, and sun. Many users choose woven shade net for long-term outdoor use.

The material holds its shape over time. Woven shade net does not sag or deform easily. This makes it a reliable choice for permanent structures.

Shade Density

Woven shade net provides higher shade rates than knitted types. The close weave blocks more sunlight and offers better protection for sensitive plants. Users can select different shade percentages based on their needs.

Woven shade net reduces light penetration more effectively. This feature helps control temperature and light in greenhouses and nurseries. The net also protects against strong winds.

Installation

Woven shade net requires careful installation. The material does not stretch, so users must measure and cut it accurately. Edge tapping is important to prevent the fabric from unraveling.

Woven shade net is heavier than knitted net. Installers may need extra support or fasteners for large areas.

Uses

Farmers use woven shade net to protect crops from intense sunlight and wind. The net works well for carports, livestock shelters, and construction sites. Many commercial growers prefer woven shade net for its strength and stability.

Woven shade net also suits areas with extreme weather. The material lasts for many seasons with minimal maintenance. Users often select woven shade net for permanent or semi-permanent installations.

Knitted and Woven Shade Net Comparison

Key Differences

The table below shows the main differences between knitted shade net and woven shade net. Each shade net type offers unique features for different needs.

| Feature | Knitted Shade Net | Woven Shade Net |

|---|---|---|

| Stretchability | High | Low |

| Durability | Good in moderate climates | Excellent in harsh weather |

| Installation | Easy, no edge taping | Requires edge taping |

| Cost | Usually lower | Often higher |

| Shade Density | Moderate to high | High |

Knitted shade net stretches and adapts to many surfaces. Woven shade net stays firm and holds its shape.

Pros and Cons

Knitted Shade Net:

- Pros:

- Stretches easily and resists tearing.

- Simple to install and cut.

- Offers good airflow and moderate protection.

- Cons:

- May not last as long in extreme weather.

- Lower shade density than woven types.

Woven Shade Net:

- Pros:

- Provides strong protection against sunlight and wind.

- Maintains shape over time.

- Works well for permanent installations.

- Cons:

- Harder to install and needs edge taping.

- Less flexible and heavier.

Applications

Knitted shade net suits gardens, patios, and temporary structures. People use it for seasonal crop protection and animal enclosures. The net allows air to flow and helps prevent heat buildup.

Woven shade net fits greenhouses, carports, and commercial farms. It offers strong protection in areas with harsh weather. Users choose woven shade net for long-term and high-density shade needs.

Both types help shield plants and outdoor spaces. The right choice depends on climate, installation needs, and the level of protection required.

Choosing the Right Shade Net

Factors

Climate plays a major role in choosing a shade net. Hot and dry regions need shade cloth with high resistance to UV rays. Humid areas benefit from shade net with good airflow.

Purpose determines the type of shade net required. Farmers use agricultural shade net to protect crops from sunlight and wind. Builders rely on construction shade net for safety and dust control.

Budget affects the selection process. Knitted shade net costs less and suits temporary setups. Woven shade cloth lasts longer and fits permanent installations.

Conclusion

Knitted shade net offers flexibility and easy installation. Woven shade net provides higher shade density and durability for harsh climates.

For temporary setups, knitted shade net works best. For permanent structures, woven shade net stands out.

Readers can choose the right shade net by considering climate, purpose, and budget. Each type supports healthy plant growth and outdoor comfort.