Understanding Winter Concrete Challenges

Understanding Winter Concrete Challenges

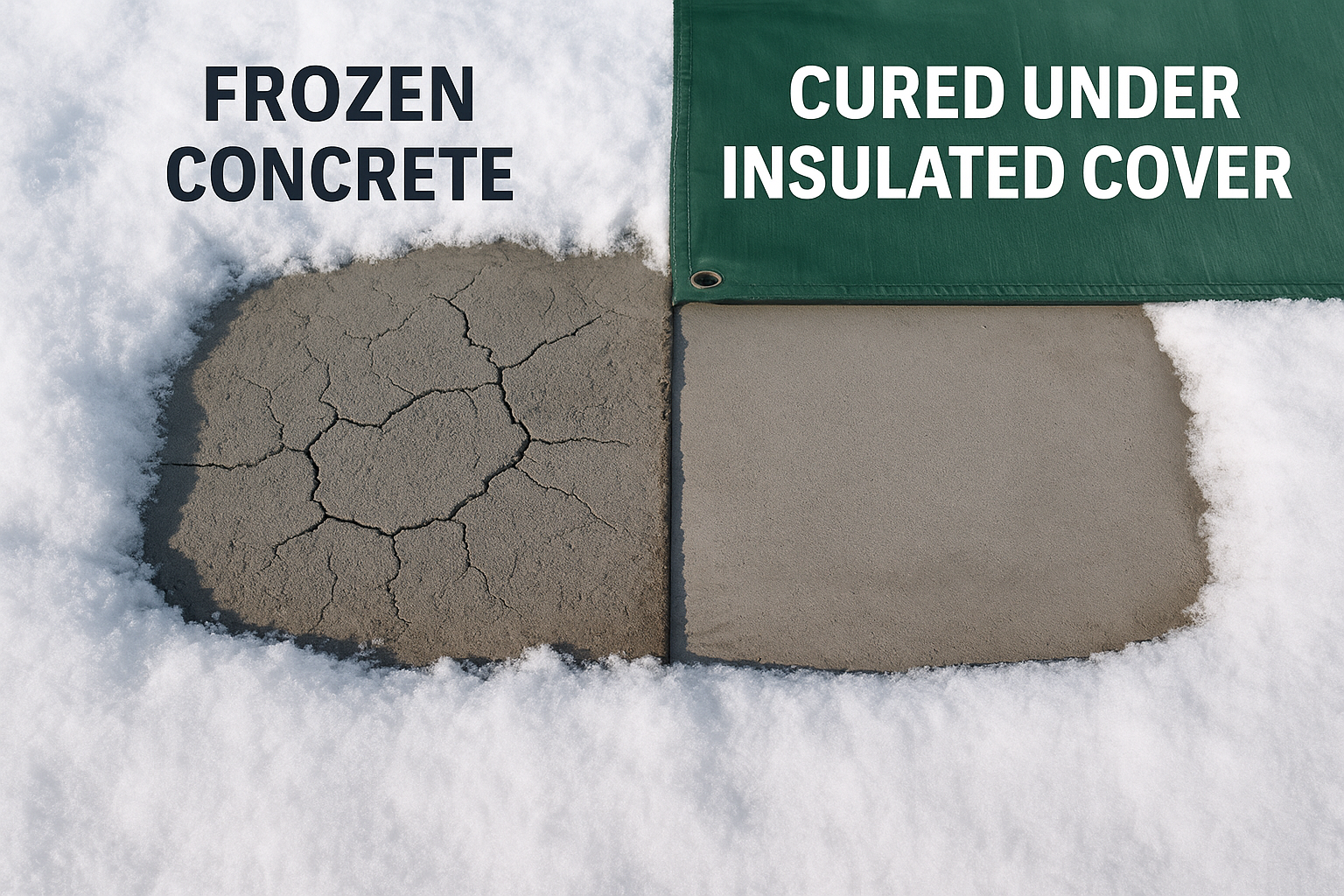

Winter construction poses multiple threats to the integrity and schedule of concrete pours. When ambient temperatures drop below ~5 °C (40 °F), the hydration reaction of cement slows significantly—or even halts—leading to weaker structure, delayed strength gain, and increased risk of damage.

For example, one source notes that when average daily temperature falls and remains low, the chemical reactions that strengthen concrete slow down and can lead to weaker concrete.

Additionally, if concrete freezes before it reaches sufficient strength, internal expansion of ice can disrupt paste-aggregate bonds, creating micro-cracks that reduce durability and increase long-term maintenance costs.

Given these risks, contractors, site managers, equipment suppliers—must adopt preventive strategies rather than reactive fixes.

What Are Insulated Tarps and How They Work

Insulated Tarps are heavy-duty covering systems specifically designed for cold-weather applications.

They combine waterproofing, wind resistance, and thermal insulation into a single product, creating a “micro-environment” over freshly poured concrete. Typical structure:

-

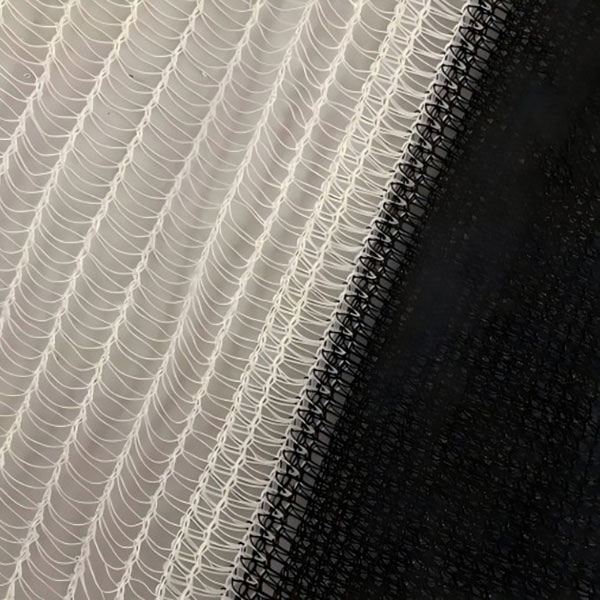

Outer layer: durable waterproof fabric (PVC, coated polyethylene) that resists snow/rain and wind penetration.

-

Insulation core: closed-cell foam, bubble-foam composite or similar, that slows heat transfer from the concrete to the ambient cold air.

-

Inner layer: reflective film or high-density polyethylene that helps retain radiant heat and prevents heat loss upward.

The result: by covering the concrete immediately after finishing, an Insulated Tarp helps maintain surface and near-surface temperatures long enough for curing processes to occur efficiently—even in cold conditions. One industry article states: “Insulating tarps help regulate temperature during construction projects, which is essential to maintaining the curing process and final strength of concrete.”

The advantage is clear: fewer delays, less reliance on energy‐intensive heating, and consistent strength development.

Why Insulated Tarps Are Essential for Concrete Care in Winter

Here are the key business and technical benefits of using Insulated Tarps for winter concrete work:

-

Thermal Retention: When concrete is protected immediately, the surface temperature remains elevated—often above 10 °C—allowing hydration to proceed. Without such protection, surface temperatures can drop dramatically, significantly extending cure times. According to some cold-weather curing guidelines, using insulation or enclosures is required once the daily average temperature falls under 4.5 °C.

-

Freeze Protection: Fresh concrete is vulnerable until its strength reaches a safe threshold. Covering with Insulated Tarps prevents frost intrusion, ice formation, and the expansion of freeze-thaw cycles on early strength.

-

Energy Efficiency: Compared to active heating (space heaters, heated enclosures), passive insulation via tarps uses far less energy, reducing operational cost and simplifying logistics. A comparison guide points out that insulated tarps are a viable alternative to heated blankets/enclosures.

-

Project Schedule Protection: When curing proceeds as required, contractors can meet deadlines and avoid rework or structural remediation due to winter damage.

-

Asset Longevity & Reuse: High-quality Insulated Tarps can be reused across multiple pours or seasons, improving return on investment. From a B2B procurement standpoint, they become a durable asset rather than a “one-time fix”.

Given these benefits, for any cold-weather job involving concrete—foundations, slabs, large pours—the specification of Insulated Tarps should be part of the risk-mitigation and procurement strategy.

For a specific product example, refer to: https://www.agrishade.com/product/insulated-tarps-for-cold-weather-construction-concrete/

Step-by-Step Guide: How to Use Insulated Tarps on Site

For clients, it’s critical to translate product specification into effective on-site process. Here’s a robust workflow:

Step 1 – Site Preparation

Before pouring, ensure the base is prepared: remove snow, ice, and standing water; make sure any frozen ground is thawed and dry. Pouring onto frozen ground or substrate undermines bond and cure.

Additionally, if possible, pre-heat or cover the substrate 24 hours in advance to stabilize thermal conditions under the tarp.

Step 2 – Placement of Insulated Tarps

Once the concrete is placed, struck off, and initial bleed water has evaporated, deploy the Insulated Tarps immediately. Coverage should exceed the pour area with sufficient overlap (10–15 cm minimum) on all sides to minimize heat escape.

Step 3 – Sealing & Securing

Fix the edges with sandbags, concrete blocks or heavy boards to prevent wind uplift. Ensure there are no gaps where cold air can infiltrate. In windy conditions, anchoring is especially important to maintain insulation integrity.

Step 4 – Monitoring & Maintaining

Install surface or embedded temperature sensors to monitor concrete surface and near-surface temperatures. The goal is to keep these within a threshold (for example 10-15 °C) until the concrete reaches a safe strength. Cold weather curing best practices recommend constant monitoring.

Also periodically inspect the tarps for damage, moisture infiltration, or displacement.

Step 5 – Removal & Post-Curing Care

After the defined curing period (often 48–72 hours, depending on mix, ambient conditions, and project specs), remove the tarps gradually to avoid sudden exposure to cold air, which can shock the top surface. Continue monitoring concrete strength—even after tarp removal, ambient cold may slow final strength gain.

For larger pours or prolonged cold periods, keep tarps in place longer or complement with temporary enclosures/heaters if required.

By following this step-by-step workflow, Insulated Tarps become more than just a product—they become a process tool in winter concrete quality assurance.

Best Practices for Using Insulated Tarps in Cold Climates

To maximize both performance and lifespan of the tarps, consider the following best practices:

-

Inspect Before Each Use: Check for tears, delamination of insulation layer, or water ingress in seams. A damaged tarp loses significant insulating potential.

-

Layering in Extreme Cold: When ambient temperatures dive below ~‐20 °C or wind chill is high, consider double coverage or combining with a secondary insulating layer. Some manufacturers recommend multi-layer solutions for extreme conditions.

-

Proper Storage: After each use, clean off concrete residue, let the tarp dry thoroughly, roll (rather than fold) into storage to prevent damage to the foam core.

-

Wind & Moisture Management: Recognize that heat loss isn’t just about ambient air temperature—wind can rapidly reduce surface temperature. Tarps must be anchored firmly and sealed well.

-

Integration with Other Measures: In very large or critical pours, use Insulated Tarps in conjunction with windbreaks, partial enclosures, or minimal heating for optimal results.

-

Documentation & Monitoring: Maintain a log of temperatures, tarp placement/removal, ambient conditions. For B2B projects, this data helps in quality assurance, client reporting, and future process optimization.

Implementing these practices ensures the tarps will deliver both thermal performance and operational reliability—not just now, but across multiple projects.

Comparing Insulated Tarps with Alternative Concrete Protection Methods

When constructing in cold weather, decision-makers often compare several protection strategies: Insulated Tarps, heated blankets/enclosures, and standard tarps. Here’s a comparative view:

| Method | Energy Use | Reusability | Coverage Scalability | Typical Cost |

|---|---|---|---|---|

| Insulated Tarps | Low | High | Large pours easily | Moderate upfront, strong ROI |

| Heated blankets / enclosures | High | Medium | Smaller areas | High initial & operational cost |

| Standard Tarps (no insulation) | Very Low | Low | Only for basic cover | Low cost, limited protection |

For extreme weather concrete works, Insulated Tarps are recommended when heat‐retention is essential.

From a procurement perspective, Insulated Tarps offer a balance of protection, scalability, and cost that suits industrial-grade construction applications. Standard tarps may suffice for non-critical cover, but not for temperature sensitive operations.

Choosing the Right Insulated Tarps for Your Project

For buyers and project managers, selecting the right Insulated Tarps involves key evaluation criteria:

-

R-Value / Thermal Rating: Higher R-value means better insulation. As per manufacturer data, certain foam/foil blankets achieve R-values of 4–5 under air-space conditions.

-

Material & Construction Quality: Look for closed-cell foam cores, heavy-duty outer fabric, reinforced hems and grommets. Check for waterproofing and UV resistance.

-

Size & Fit to Pour Area: The tarp should cover not just the pour surface, but also overlap edges and allow for anchoring. Custom sizing may be necessary.

-

Waterproofing & Wind Resistance: Outdoor winter conditions may include snow, wind, and rain. The tarp must resist water ingress and wind uplift.

-

Supplier Documentation & Service: For B2B procurement, you’ll want product specs, certifications, and perhaps custom options.

-

Logistics and Lifecycle Costs: Consider storage, cleaning, reuse across multiple projects, and replacement cycle in your business case.

By aligning the selection process with operational needs—pour size, climate, schedule constraints—procurement can ensure that Insulated Tarps deliver predictable performance.

Conclusion

Winter concreting doesn’t have to mean compromised quality or delayed schedules. By integrating Insulated Tarps into your cold-weather strategy, B2B clients—whether contractors, site managers or suppliers—gain a practical, cost-effective tool for maintaining the cure environment, protecting structure integrity, and optimizing energy use.

From proper material specification to on-site deployment, monitoring and lifecycle management, the use of Insulated Tarps becomes an operational discipline, not just a product choice. In doing so, projects mitigate risk, control costs, and maintain schedule in even the harshest conditions.