High-density polyethylene stands out as a durable plastic known for its impressive strength and flexibility.

HDPE supports a wide range of industries by offering reliable performance in harsh conditions. Manufacturers often choose hdpe for mesh products because it resists moisture, chemicals, and UV rays. Many solutions from agrishade, such as shade nets and plant protection meshes, use hdpe to deliver long-lasting results.

High-Density Polyethylene Overview

What Is High-Density Polyethylene?

High-density polyethylene is a thermoplastic polymer that offers outstanding durability and versatility. Manufacturers rely on hdpe for its unique combination of strength and flexibility.

This material supports a wide range of mesh products, including agricultural shade nets and protective screens.

The structure of hdpe features tightly packed molecules, which gives it a higher density and improved material properties compared to other polyethylenes. These properties make hdpe a preferred choice for applications that demand stability and long-term performance.

Key Properties of HDPE

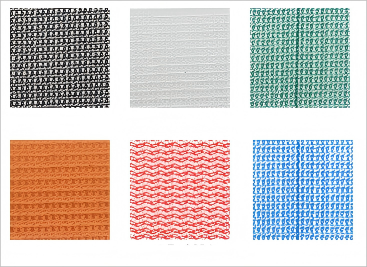

HDPE offers a range of properties that make it valuable for mesh products. These properties include high tensile strength, excellent impact and chemical resistances, and superior moisture resistance.

The material properties of hdpe allow it to withstand harsh weather, UV exposure, and contact with chemicals. Mesh products made from hdpe maintain their shape and function over time, even in demanding environments.

| Property | Description |

|---|---|

| Tensile Strength | Resists stretching and tearing |

| Chemical Resistance | Withstands exposure to acids and bases |

| Moisture Resistance | Prevents water absorption and damage |

| UV Stability | Maintains integrity under sunlight |

| Flexibility | Adapts to various shapes and uses |

The material properties of hdpe also include lightweight construction and ease of handling. These features simplify installation and maintenance for mesh solutions.

HDPE’s chemical resistance protects mesh products from degradation, while its moisture resistance ensures long-lasting performance outdoors. The combination of these properties makes hdpe an essential material for protective netting and shade applications.

Tip: When selecting mesh products for outdoor use, consider hdpe for its proven durability and reliable material properties.

Common Uses of HDPE

Shade Net Products and Netting Solutions

HDPE stands out as the preferred material for shade net products and netting solutions. These applications demand durability, flexibility, and resistance to environmental factors. Mesh products made from hdpe serve a variety of purposes, including shade, protection, and privacy.

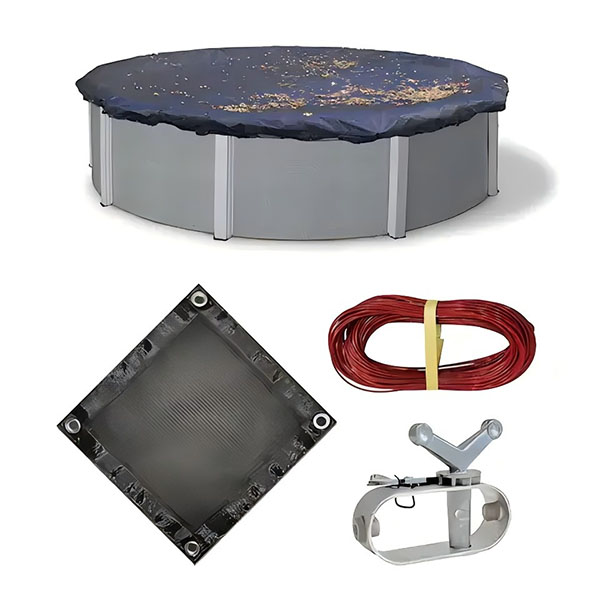

Agrishade offers a range of hdpe mesh products, such as shade net, plant protection net, sun shade sails, construction safety net, pool cover, outdoor privacy screen, PE tarpaulin, insulated tarps, and sports net.

These products demonstrate the versatility of hdpe in real-world applications. Farmers use shade nets and plant protection nets to shield crops from harsh sunlight and pests. Construction teams rely on safety nets to prevent accidents and protect workers. Homeowners install pool covers and privacy screens to enhance safety and comfort.

| Mesh Product | Primary Use | Benefits of HDPE |

|---|---|---|

| Shade Net | Crop protection | UV resistance, flexibility |

| Plant Protection Net | Pest control | Chemical resistance, durability |

| Sun Shade Sails | Outdoor shading | Moisture resistance, strength |

| Construction Safety Net | Worker safety | Impact resistance, stability |

| Pool Cover | Water safety | Lightweight, easy handling |

| Outdoor Privacy Screen | Privacy enhancement | Weather resistance, longevity |

| PE Tarpaulin | Shelter and coverage | Tear resistance, adaptability |

| Insulated Tarps | Temperature control | Insulation, durability |

| Sports Net | Recreational use | Flexibility, impact resistance |

HDPE mesh products offer reliable performance in demanding environments. Farmers, builders, and homeowners choose hdpe mesh solutions for their ability to withstand weather, chemicals, and physical stress. The material’s lightweight nature simplifies installation and maintenance.

HDPE’s resistance to UV rays and moisture ensures that mesh products retain their shape and function over time.

Tip: When selecting mesh products for outdoor use, consider hdpe for its proven durability and long-lasting protection.

HDPE continues to set the standard for mesh and netting applications. Its unique properties make it the material of choice for products that require stability, safety, and adaptability. People benefit from hdpe mesh solutions in agriculture, construction, recreation, and home improvement.

HDPE Benefits and Drawbacks

Advantages of HDPE

HDPE offers several advantages that make it a popular choice for shade nets products. This material provides high impact strength, which helps mesh netting withstand physical stress and harsh weather.

Many users value hdpe for its lightweight nature, making installation and handling easier. The material resists moisture and chemicals, so it performs well in outdoor environments. HDPE also stands out for its UV stability, which helps mesh products last longer under sunlight.

The versatility of hdpe supports a wide range of applications, from agricultural shade nets to construction safety mesh. Farmers and builders trust hdpe mesh for its durability and flexibility.

The material’s resistance to corrosion makes it ideal for corrosion resistant piping and mesh solutions exposed to chemicals. HDPE also supports safe food storage, as seen in containers and packaging. Its non-toxic nature ensures that it does not contaminate food or water.

Note: HDPE’s combination of strength, flexibility, and chemical resistance sets it apart from many other plastics

Disadvantages of HDPE

Despite its many benefits, hdpe has some drawbacks. The material can become brittle at very low temperatures, which may limit its use in extremely cold climates. HDPE mesh products may also deform under heavy loads or prolonged stress. While hdpe resists many chemicals, it does not perform well with strong oxidizing agents.

HDPE is less rigid than some other plastics, so it may not provide enough structural support for certain applications. The production of hdpe relies on fossil fuels, which raises environmental concerns. Recycling rates for hdpe mesh products remain lower than for some other materials, even though the material itself is recyclable.

HDPE vs Other Polyethylenes

HDPE vs LDPE

High-density polyethylene and low-density polyethylene represent two of the most common types of polyethylene. Both materials serve important roles in mesh product manufacturing, but they differ in several key ways. HDPE features a tightly packed molecular structure, which gives it greater strength and rigidity. LDPE, on the other hand, has a more branched structure, resulting in a softer and more flexible material.

| Property | HDPE | LDPE |

|---|---|---|

| Density | Higher | Lower |

| Strength | Greater tensile strength | Lower tensile strength |

| Flexibility | Moderate | High |

| UV Resistance | Excellent | Moderate |

| Durability | Superior for outdoor use | Less durable outdoors |

HDPE mesh products often last longer in outdoor environments. They resist UV rays and harsh weather better than LDPE mesh. LDPE mesh may suit applications that require extra flexibility, but it does not provide the same level of protection or longevity.

Other Polyethylene Comparisons

Polyethylene comes in several forms, each with unique properties. Besides HDPE and LDPE, manufacturers sometimes use linear low-density polyethylene (LLDPE) for mesh products.

LLDPE offers a balance between flexibility and strength, but hdpe still leads in terms of rigidity and weather resistance.

Key differences among polyethylene types:

- HDPE: Best for strength, UV resistance, and long-term outdoor use.

- LDPE: Best for flexibility and lightweight applications.

- LLDPE: Offers a middle ground, with moderate strength and flexibility.

HDPE remains the preferred choice for mesh products that require stability and protection. Its superior material properties help ensure reliable performance in agriculture, construction, and outdoor privacy solutions.

Environmental Impact of HDPE

Recyclability

High-density polyethylene stands out as one of the most recyclable plastics in use today. Many recycling centers accept hdpe mesh products because they are easily recyclable.

The recycling process involves collecting used mesh, cleaning it, and then melting it down to create new products. This cycle reduces the need for new raw materials and helps lower overall waste. Mesh products made from hdpe often carry a recyclable symbol, making it clear to users that they can participate in plastic recycling programs.

Recycling hdpe mesh products supports a circular economy. When people recycle these materials, manufacturers can produce new mesh solutions without relying solely on virgin resources.

This process conserves energy and reduces the environmental footprint of plastic production. The durability of hdpe also means that mesh products can be reused multiple times before recycling becomes necessary.

Sustainability in Mesh Products

Sustainability remains a key advantage of hdpe mesh products. The long lifespan of shade nets means fewer replacements and less waste over time. Mesh products resist weather, chemicals, and UV rays, so they maintain their function for years.

This durability reduces the frequency of disposal and replacement, supporting sustainable practices.

Agrishade’s mesh products use hdpe to deliver both performance and environmental benefits. By choosing recyclable materials, the company helps reduce landfill waste and encourages responsible resource use.

The lightweight nature of hdpe mesh also lowers transportation emissions, as shipping requires less fuel. These factors combine to make hdpe mesh products a smart choice for those who value sustainability.

Note: Selecting recyclable mesh products made from hdpe supports both environmental protection and long-term cost savings.

Conclusion

High-density polyethylene offers strength, flexibility, and resistance to harsh conditions. HDPE mesh products provide reliable solutions for agriculture, construction, and outdoor spaces.

Users benefit from long-lasting performance and recyclability. While hdpe has some drawbacks, its advantages often outweigh them. Those interested in sustainable mesh solutions can explore options like those from agrishade or seek more information from industry experts.