Learn how to choose the right Sun Shade Netting Material for your garden, patio, or greenhouse. This guide explains material types, shade density, color options, and construction styles to help you find the best sun protection for plants and outdoor spaces. Make informed decisions to boost durability, airflow, and comfort with the ideal sun shade netting solution.

Key Factors for Sun Shade Selection

Assessing Your Needs

You should start by thinking about where you want to use shade netting. A garden, greenhouse, or patio each has different needs. Plants in a greenhouse may need a different shade net than a patio sitting area.

If you want to protect vegetables, you may need a lighter shade netting. For outdoor seating, you might want a denser shade cloth. You should also consider how much sunlight your area gets during the day.

Main Selection Criteria

When you choose shade netting, you need to look at several key points. The material of the shade net affects how long it lasts and how well it blocks the sun. Shade cloth made from high-density polyethylene (HDPE) or other strong fibers can last longer outdoors.

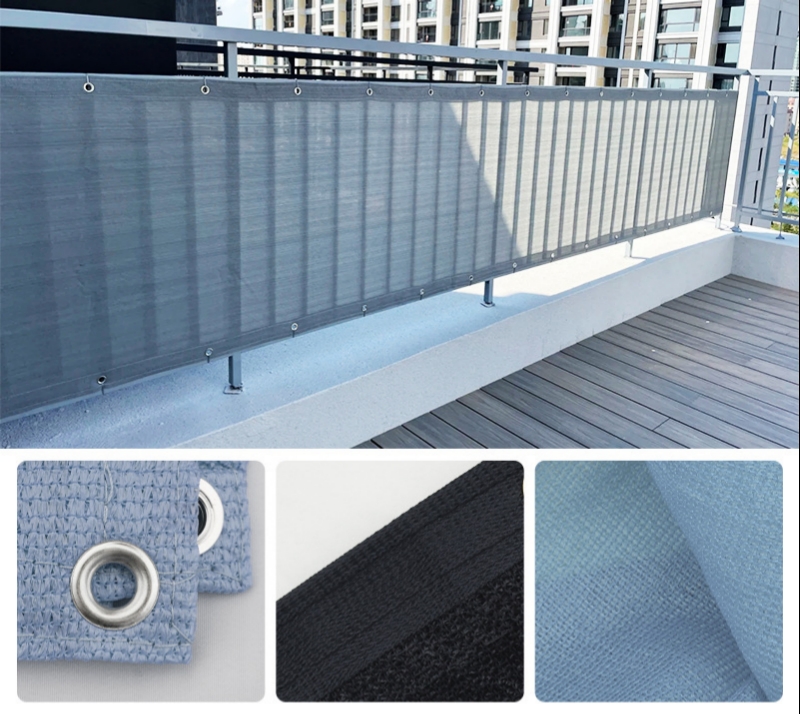

The construction of the shade net also matters. Knitted shade netting gives you better airflow and resists tearing. Woven shade cloth offers more strength but less flexibility.

Shade density tells you how much sunlight the shade fabric blocks. For most gardens, a 30% to 50% shade net works well. For patios or greenhouses, you may want a 70% or higher shade cloth.

Color also plays a role. Darker shade netting absorbs more heat, while lighter shade fabric reflects sunlight. You should match the color of your shade net to your climate and the needs of your plants or outdoor space.

Sun Shade Netting Materials

HDPE and Polyethylene

You will find that most shade netting uses high-density polyethylene (HDPE) or regular polyethylene (PE). These plastics offer strong UV resistance and last for years outdoors. HDPE shade netting feels lightweight but holds up well in sun and rain.

Polyethylene shade net also resists mold and mildew, which helps your shade fabric stay clean. Many gardeners choose HDPE because it allows good airflow and does not stretch out of shape. Polypropylene sometimes appears in shade netting, but HDPE and PE remain the most common choices.

Polyester and Vinyl-Coated Options

Polyester shade netting gives you a different set of benefits. This material feels soft but stays strong under tension. Polyester shade net resists tearing and handles wind well. Some manufacturers add a vinyl coating to polyester shade netting. This coating increases water resistance and blocks more UV rays.

Vinyl-coated polyester shade netting often lasts longer in harsh weather. Polypropylene can also be coated for extra protection, but you will see it less often than polyester or HDPE.

| Material | UV Resistance | Durability | Water Resistance | Common Use |

|---|---|---|---|---|

| HDPE | High | High | Good | Gardens, patios |

| Polyethylene | High | Medium | Good | Greenhouses |

| Polyester | Medium | High | Medium | Outdoor seating |

| Vinyl-Coated Poly | Very High | Very High | Excellent | Commercial spaces |

| Polypropylene | Medium | Medium | Good | Temporary covers |

Knitted vs. Woven Construction

You need to choose between knitted and woven shade netting. Knitted shade netting uses interlocking loops, which makes it flexible and hard to tear. This type of shade netting allows more air to pass through, so your plants stay cooler.

Woven shade netting uses crisscrossed threads, which creates a tighter and stronger shade fabric. Woven shade netting blocks more sunlight but can trap heat. Polypropylene shade netting often comes in both knitted and woven forms, but knitted HDPE shade netting remains the most popular for gardens.

- Knitted Shade Netting

- Flexible and lightweight

- Resists unraveling if cut

- Best for gardens and greenhouses

- Woven Shade Netting

- Strong and durable

- Holds its shape well

- Good for patios and permanent structures

Comparison of Sun Shade Netting Materials

Selecting the right sun shade netting material is essential for ensuring durability, light control, and long-term performance in commercial environments. Below is a comparison of the most common materials used in agricultural and industrial shade nets:

| Material | Key Features | Best For |

|---|---|---|

| HDPE (High-Density Polyethylene) | UV-stabilized, tear-resistant, lightweight, long-lasting | Greenhouses, nurseries, crop fields |

| Aluminet (Reflective Shade Cloth) | Reflects heat, reduces temperature, enhances light diffusion | Climate control in greenhouses, floriculture |

| Polypropylene | Lightweight, moderate strength, less expensive | Temporary installations, general garden use |

| Knitted Monofilament | Flexible, resists unraveling, high UV resistance | Windbreaks, shade for livestock, outdoor coverings |

| Woven Polyethylene | Strong, durable, less breathable, may fray at edges | Construction sites, debris protection, fencing |

Key Considerations for Buyers

- UV Stability: HDPE and knitted monofilament offer excellent long-term sun protection.

- Ventilation: Knitted options allow better airflow; woven materials provide dense coverage.

- Durability: Choose based on environmental conditions and duration of use.

- Customization: Most materials support custom shade percentages, widths, and roll lengths.

Recommended Use by Industry

Agriculture

For commercial farming operations, HDPE knitted shade nets are the top choice due to their durability, UV stability, and flexibility. Available in 30% to 80% shade, they help regulate sunlight exposure for crops like vegetables, berries, and field-grown plants. These nets enhance photosynthesis efficiency, reduce heat stress, and minimize water evaporation—making them ideal for large-scale open-field and greenhouse cultivation.

Horticulture

In nurseries, greenhouses, and ornamental plant production, Aluminet or high-quality HDPE shade cloths are recommended. Aluminet’s reflective properties help maintain a cooler environment and even light diffusion, critical for temperature-sensitive crops such as orchids, ferns, and flowering plants. HDPE variants offer long-term value and can be customized for specific shade levels and growth stages.

Construction

For building sites and scaffolding coverage, woven polyethylene shade netting offers strong physical protection. It’s used for dust control, debris containment, and worker safety, especially in urban construction zones. With reinforced edges and tear resistance, these nets meet both performance and safety compliance needs in commercial and industrial projects.

Livestock

To protect animals from extreme heat and direct sunlight, 70% to 90% knitted shade nets are commonly used in livestock farms, dairies, and poultry enclosures. These nets help reduce heat stress, improve animal welfare, and support higher productivity. Their breathable design allows for ventilation while maintaining effective shading across barns, pens, and feedlots.

Conclusion

Choosing the right Sun Shade Netting Material is essential for creating an effective and long-lasting shade solution. By understanding the differences in material types, construction styles, shade densities, and colors, you can match the right netting to your specific needs—whether for gardening, greenhouse use, or outdoor living.

A well-selected shade net not only protects plants and people from harsh sunlight but also improves comfort, reduces heat, and extends the life of your outdoor space. Make thoughtful choices today for healthier plants and better sun protection tomorrow.