A debris net is a mesh barrier designed to catch and contain falling debris on construction sites. This crucial safety measure shields workers and the public from injury or damage. Debris nets offer protection by acting as temporary fall protection systems, preventing objects from leaving the work area. Site managers rely on debris nets to improve job site safety and meet personnel fall protection requirements.

What Is a Debris Net

Debris Netting Definition

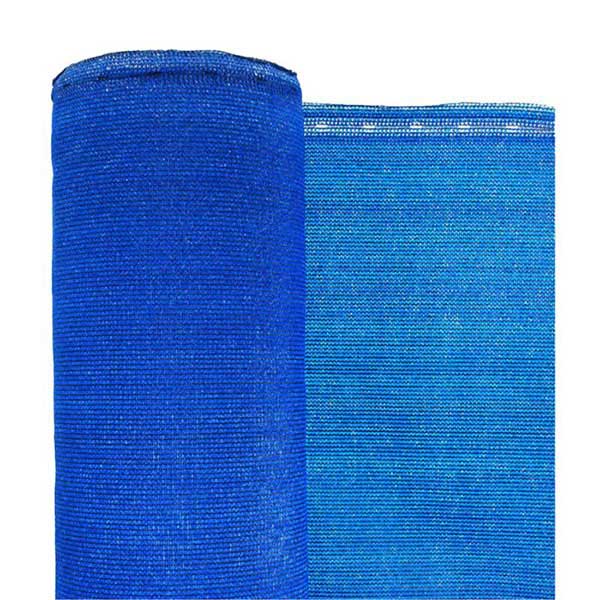

Debris net is a type of mesh fabric used to catch and contain loose materials that may fall from elevated work areas. This netting acts as a protective barrier on construction sites. It helps keep tools, bricks, wood, and other objects from dropping to lower levels or outside the work zone. Debris netting is designed to be strong and flexible. It can stretch across scaffolding, building frames, or open spaces where falling debris is a risk.

Tip: Debris netting is not the same as safety netting. Safety netting is built to catch people who fall, while debris netting is made to stop objects from falling.

Main Purpose and Use

The main purpose of debris netting is to improve safety by preventing injuries and property damage. Workers use debris netting to protect themselves and others from falling objects. Site managers install debris netting around scaffolding, building edges, and walkways. This netting also helps keep construction sites clean by containing dust and small debris.

Common uses for debris netting include:

- Surrounding scaffolding to block falling materials

- Covering building perimeters during demolition or renovation

- Creating barriers around walkways and entry points

- Acting as debris containment netting for high-rise projects

Key Features and Materials

Debris netting comes with several important features. These features help it perform well in tough environments.

| Feature | Description |

|---|---|

| Mesh Size | Varies to block different sizes of debris |

| Material | Usually made from high-density polyethylene |

| UV Resistance | Protects netting from sun damage |

| Fire Retardant Option | Reduces fire risk on construction sites |

| Color Choices | Often available in green, blue, or black |

| Custom Sizes | Can be cut or ordered to fit specific areas |

Most debris netting uses high-density polyethylene. This material is lightweight, strong, and weather-resistant. Some netting includes fire retardant treatments for extra safety. Mesh size can be selected based on the type of debris expected. Smaller mesh blocks dust and tiny particles, while larger mesh stops bricks or tools.

Note: Choosing the right mesh size and material is important for effective debris containment and safety.

How Debris Netting Works

Barrier Against Falling Debris

Debris netting forms a strong shield around construction areas. It stretches across scaffolding and open spaces to stop falling debris. When objects slip or drop from high places, the netting catches them before they can fall to the ground. This barrier helps prevent injuries and keeps the work area safer for everyone. The netting also reduces the risk of debris leaving the site and causing harm to people or property nearby. By stopping falling debris, debris netting supports fall protection efforts on every job site.

Debris Net vs. Other Nets

Not all nets serve the same purpose. Debris netting is designed to catch objects, not people. Safety nets for fall protection must meet different safety standards. These nets are thicker and stronger because they need to catch a person in case of a fall. Debris netting uses a lighter mesh that blocks small and large debris but does not provide the same level of fall protection for workers. Some sites use both types of nets together to cover all risks.

Note: Always check which type of netting is needed for each task. Using the wrong net can lead to safety problems.

Safety and Compliance

Construction sites must follow strict safety standards. Debris netting helps meet these rules by controlling falling debris and supporting fall protection systems. Many safety standards require barriers to stop objects from falling off buildings or scaffolding. Regular checks ensure the netting stays in good shape and continues to protect workers and the public. Meeting these standards is important for every project. Proper use of debris netting shows a commitment to safety and helps avoid fines or shutdowns.

Debris Netting Installation

Installation Methods

Debris netting installation begins with planning. Workers measure the area that needs coverage. They select the right netting size and type for the job. Most debris netting attaches to scaffolding, frames, or building edges. Workers use cable ties, ropes, or hooks to secure the netting. Each attachment point must be tight to prevent gaps. Some sites use clips or special fasteners for extra strength. The netting should hang with enough tension to catch falling debris. Loose netting may fail to stop objects. Teams check the netting after installation to make sure it covers all risk zones.

Tip: Always inspect the netting before and after installation. Look for tears or weak spots.

Installation steps often include:

- Measure the area for coverage.

- Choose the correct netting size and material.

- Attach netting to support structures using ties or hooks.

- Check for secure attachment at every point.

- Inspect the finished installation for safety.

Mesh Size and Customization

Mesh size plays a key role in debris netting installation. Small mesh blocks dust and tiny particles. Large mesh stops bricks, wood, or tools. Workers select mesh size based on the type of debris expected. Material choice also matters. High-density polyethylene works well for most sites. Fire retardant netting adds safety in areas with heat risks. Custom sizes fit unique spaces or shapes. Some projects need colored netting for visibility or site rules.

| Mesh Size | Best For |

|---|---|

| Small (2-5mm) | Dust, small debris |

| Medium (10mm) | Tools, wood pieces |

| Large (20mm+) | Bricks, heavy items |

Proper mesh size and material selection help meet safety requirements. Customization ensures debris netting installation fits each site’s needs.

Safety Benefits of Debris Netting

Worker and Public Protection

Debris netting provides a strong layer of protection for everyone near construction sites. Workers face risks from falling debris every day. The netting acts as a shield, catching falling objects before they can cause harm. This barrier helps prevent injuries on scaffolding and walkways. People passing by demolition sites also benefit from this containment. The netting keeps debris from leaving the work area and reaching public spaces.

Note: Debris containment is essential for both workers and the public. It reduces the chance of accidents caused by falling debris or tools.

Debris netting also helps control dust and small particles. This makes the air cleaner and safer to breathe. The netting creates a safer environment for everyone around the site.

Preventing Property Damage

Falling objects can damage cars, windows, and nearby buildings. Debris netting stops these objects before they reach the ground. This containment protects property near construction and demolition sites. The netting holds back bricks, wood, and other materials that might otherwise cause costly repairs.

Many demolition sites use debris netting to keep heavy debris from spreading. This debris containment is important for areas with high foot traffic or valuable property. The netting also helps keep sidewalks and roads clear. This makes it easier for people to move safely around the site.

A simple table shows how debris netting helps prevent property damage:

| Risk | How Debris Netting Helps |

|---|---|

| Broken windows | Stops falling objects |

| Damaged vehicles | Provides debris containment |

| Blocked walkways | Keeps debris inside the site |

| Harm to landscaping | Prevents spread of materials |

Regulatory Advantages

Safety regulations require construction sites to control falling debris and protect people nearby. Debris netting helps meet these safety regulations by providing reliable containment. Many rules state that barriers must stop falling objects from leaving the site. Debris netting offers a simple way to follow these safety regulations.

Demolition sites often face strict safety regulations. Using debris netting shows a commitment to safety and helps avoid fines. Regular inspections of the netting ensure it meets all safety regulations. This debris containment system also makes it easier for site managers to pass safety checks.

Tip: Following safety regulations with proper debris containment can keep projects on schedule and prevent costly delays.

Debris netting supports compliance with safety regulations and helps create a safer work environment. It also builds trust with the public by showing that the site takes safety seriously.

Debris Netting Applications

Scaffolding and Perimeter Use

Debris netting serves many roles on construction sites. One of the most common uses is on scaffolding. Workers attach the netting to the outside of scaffolding to catch falling tools, bricks, or wood. This setup helps keep the area below safe for workers and pedestrians. The netting also lines building perimeters during demolition or renovation. It forms a barrier that stops debris from leaving the work zone. Some sites use debris netting as a temporary guardrail. This guardrail helps mark the edge of platforms and walkways, adding another layer of safety.

Tip: Using netting on perimeters can also help reduce wind and dust, making the site cleaner and safer.

Other Industries and Examples

Debris netting is not limited to construction sites. Many industries use this material for different purposes. In shipyards, netting protects workers from falling objects during repairs. Sports facilities use netting to keep balls and equipment inside play areas. Warehouses sometimes install netting above storage racks to prevent items from falling onto workers below. Farmers use netting as a wind barrier to protect crops. Some outdoor events use netting to provide shade or to create safe zones for visitors.

A table shows the versatility of debris netting:

| Application Area | Example Use |

|---|---|

| Construction | Scaffolding, guardrails |

| Shipyards | Overhead protection |

| Sports Facilities | Ball containment |

| Warehouses | Rack safety |

| Agriculture | Wind barrier, shade |

Debris netting adapts to many needs. Its flexible design allows it to serve as a barrier, a shield, or even a shade cover in many settings.

Maintenance and Durability

Inspection and Care

Debris netting needs regular inspection to stay effective. Workers should check the netting before each shift. Look for tears, holes, or loose attachments. Small damages can grow larger if not fixed quickly. Inspect all connection points, such as ties, hooks, or clips. Make sure the netting stays tight and covers all risk areas.

A simple checklist helps keep inspections on track:

- Check for visible damage or wear.

- Test attachment points for strength.

- Confirm the netting covers the entire area.

- Remove any debris caught in the mesh.

- Look for signs of sun damage or fading.

Tip: Clean debris netting with water and a soft brush. Avoid harsh chemicals that can weaken the material.

Proper care extends the life of debris netting. Store unused netting in a dry, shaded place. Roll or fold the netting to prevent creases. Keep it away from sharp objects that could cause cuts.

Replacement Guidelines

Debris netting does not last forever. Replace netting when it shows signs of serious wear or damage. Large holes, broken mesh, or weak spots mean the netting cannot protect the site. Sun exposure can make the material brittle over time. Fire or chemical exposure also weakens the netting.

A table can help decide when to replace debris netting:

| Condition | Action Needed |

|---|---|

| Small tears or holes | Repair if possible |

| Large or spreading holes | Replace immediately |

| Faded or brittle mesh | Replace soon |

| Damaged attachments | Repair or replace |

Note: Always follow site safety rules for replacing netting. Never use damaged netting on active construction sites.

Regular replacement keeps the work area safe. Fresh netting ensures the best protection for workers, the public, and property.

Conclusion

Debris net plays a critical role in stopping falling debris on construction sites. This protection keeps workers and the public safe from harm. Proper installation and regular care of debris netting help maintain strong protection. Debris net also prevents falling debris from damaging property. Every site should make debris net a top priority for safety. Choose the right net and follow best practices to ensure the highest level of protection.

Make safety a habit—use debris net for every project.